Low Carbon Construction

Low-Carbon, Energy-Efficient Construction

According to the 2021 report of the International Energy Agency, the building sector accounts for about 38% of global greenhouse gas emissions, and the greenhouse gas emissions in the whole life cycle of buildings include “use carbon emissions” and “contained carbon emissions”, with operational carbon emissions (OC) in the daily use phase accounting for about 28%, and embodied carbon emissions (EC) in the construction and renovation and demolition stages Emissions account for about 10 percent.

Construction engineering is the main business of RTC, and the development and introduction of carbon reduction or labor-saving technologies in the core business are the main focus of the company’s research and development in 2023 to cope with the increasingly severe global greenhouse gas effect and create the problem of labor shortage.

In terms of carbon reduction, RTC takes a two-pronged approach from the two aspects of low-carbon building projects (EC) and low-energy buildings (OC), through investigation and adjustment of the carbon footprint and carbon volume of the supply chain, customers and products, and all-round integration with new materials, new designs, new construction methods, new equipment and new technologies, in order to create buildings with lower carbon content and more energy-saving and environmentally friendly buildings.

Taiwan’s population is growing negatively, making the problem of labor shortage more and more serious, which is a problem that RTC must seriously address and try to solve in pursuit of corporate sustainability. To solve the shortage of construction workers, we can develop labor-saving technologies from the existing knowledge fields, introduce or learn from the practices of domestic and foreign counterparts, adopt mechanized and automated tools or equipment to reduce the manpower demand for operations, use software and AI technology to reduce the manpower requirements of drawing, design or engineers, and continue to pursue design rationalization, construction labor-saving, production intelligence and management informatization, etc., so as to lay the foundation for the operation of the company from generation to generation.

Near-zero-energy buildings

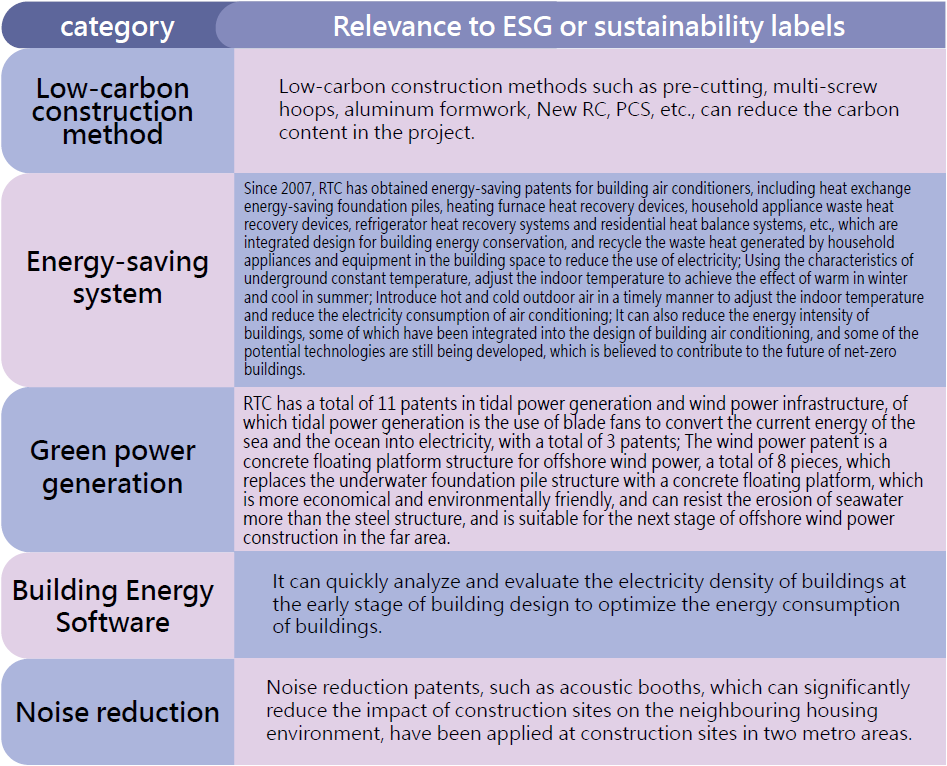

In response to the global net-zero action and Taiwan’s 2050 net-zero emission policy, RTC develops carbon reduction countermeasures with its own technology, from improving the energy efficiency of building equipment, creating carbon reduction technologies and construction methods to develop and apply, aiming to reduce the carbon footprint of construction and engineering activities on the environment, including the use of environmentally friendly construction materials, promoting energy efficiency, promoting the application of renewable energy, and reducing waste generation, and actively assisting customers to complete green buildings, low-carbon buildings, Planning, design and construction of smart buildings. In addition, RTC has also cooperated with ITRI to develop building energy consumption analysis software, which can be used as a tool to optimize building energy consumption at the early stage of design and planning, which is expected to reduce building energy consumption by 5 to 20%.

Energy saving and carbon reduction design of equipment

(building energy efficiency OC)

Green Buildings and Smart Buildings

In order to reduce the energy consumption and carbon emissions of buildings, the construction industr y reduces energy consumption and carbon footprint in different ways, pursues the effective use and management of buildings and resources, and pays attention to the indoor and outdoor environmental quality of buildings, so as to obtain green buildings and smart buildings and other labels, reduce the negative impact on the environment, and achieve sustainable development of the earth. In2023, RTC obtained 1 silver and 2 bronze grades of candidate green building certificates and 1 bronze and 1 qualified grade of candidate intelligent building certificates; In the future, it is expected that a total of 2 4 projects will be built with the sustainability certification mark, including 2 green building gold grades, 9 candidate green building gold and 6 silver grades1 Diamond, 1 Silver and 1 Bronze for Smart Buildings, 1 LEED Platinum, 2 for Gold and 1 for Qualified.

RTC has completed the I S O 14064-1 organizational inventory in the first half of 2024, with a total greenhouse gas emission of 39,689 metric tons of CO2e in 2023, and is expected to complete the ISO14067 of pre-cast component products by the end of 2024 In the future, the company will gradually build a more complete carbon data database, formulate carbon governance policies, apply and certify low-carbon construction methods, construct and revise building carbon assessment models, and ensure that carbon emissions are minimized and resilient buildings are built from the life cycle analysis of buildings, so as to face increasingly severe extreme climate challenges.

Continuous innovation and R&D

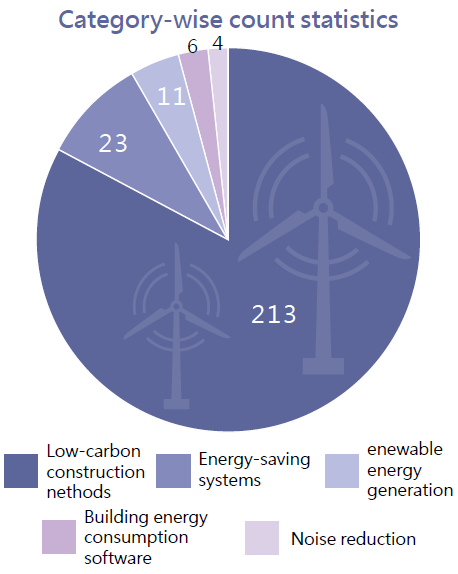

From the perspective of the building life cycle, the main goal is to reduce the carbon content of the building, and the technology development is based on pre-casting, and the development of corresponding patented technologies for major business markets such as residential, office buildings, factories, etc. Among them, the more distinctive ones are the pre-cast laminated layer construction method, the pre-cast lattice board construction method and the pre-cast seismic isolation layer construction method, etc., and these technologies have gradually become a differentiated tool for the company’s business to win orders over the years. By the end of 2023, RTC had obtained a total of 745 patents in 19 countries around the world, of which 257 patents (including patents pending) were closely related to ESG (refer to the table on the right).