Climate and environmental management

energy management

The 28th Conference of the Parties (COP28) to the United Nations Conference on Climate Change in 2023 conducted the first inventory of global carbon reduction results, and the results showed that the global progress in carbon reduction is significantly lagging behind, and the implementation performance of the Paris Agreement is not up to standard in terms of mitigation or adaptation, and there is still a certain gap between the goal of limiting the temperature rise to 1.5° C. To this end, enterprises and governments have strengthened the implementation of carbon management and carbon reduction regulations.

In 2023, Taiwan also passed the Greenhouse Gas Reduction and Management Act to amend the Climate Change Response Act, and included the 2050 net-zero emission target, codified climate governance, and promoted corporate emission reduction and reduction countermeasures, so that enterprises must formally incorporate carbon reduction actions into their business actions. In order to achieve the goal, RTC also strives to minimize the impact of its own operations on the environment, and regards carbon reduction and energy conservation as important issues in current management. In order to strengthen the internal energy and greenhouse gas management, RTC starts from the two aspects of “operation base” and “low-carbon products”, cooperates with the national net-zero emission path and strategy, carries out various strategies and implementation plans, and the Sustainable Development Committee formulates various carbon reduction implementation plans and sustainable low-carbon projects.

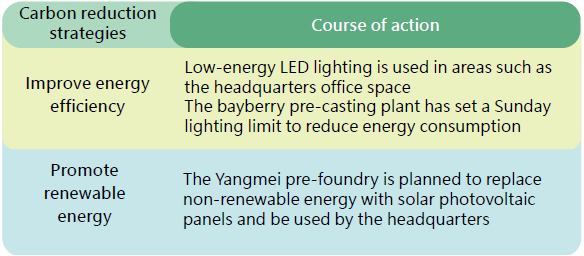

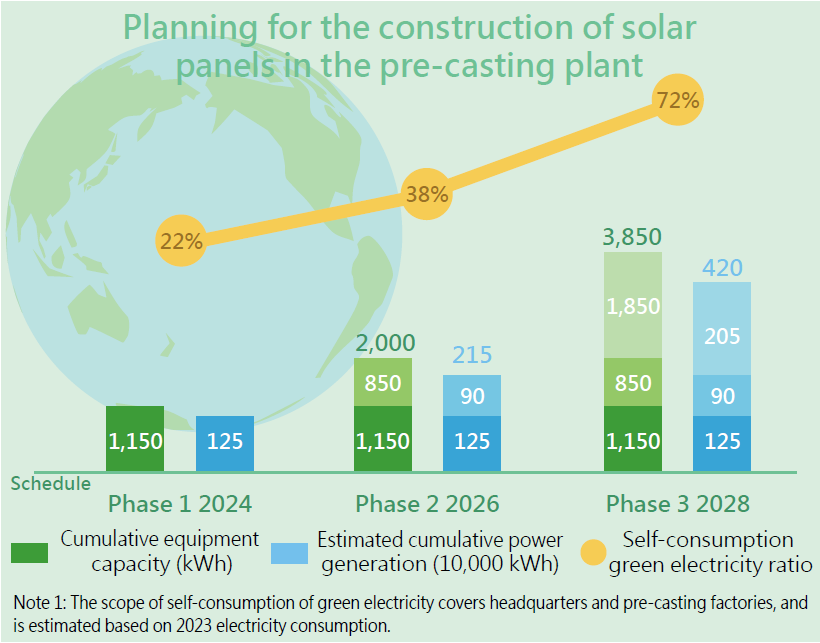

Energy conservation and carbon reduction strategies for operating sites Since the main energy use of the headquarters is purchased electricity, we plan to improve energy efficiency and use renewable energy from the perspective of power conservation. Among them, from 2024, Yunhong plans to take advantage of the unsheltered surroundings of the Yang Mei Preliminary Drilling Plant to install solar panels on the roof, and after completion, in addition to providing them for their own use, they may be sold to Taiwan Power or transferred to the parent company for use by the parent company according to the law.

Energy saving and carbon reduction strategies for low-carbon products

Construction projects have long relied on high-energy-consuming building materials such as steel bars and concrete, among which the overall amount of concrete is large, and the cementing materials contained in concrete materials account for up to 90% of carbon emissions. With carbon in buildings as the main axis, RTC fully cooperates with the government’s policies on energy conservation, carbon reduction and greenhouse gas emissions through various energy-saving and carbon-reduction actions such as low-carbon concrete, green pre-casting production, low-carbon construction methods and green supply chain.

RTC plans to develop low-carbon precast concrete, change the proportion of cementing materials in the current concrete, reduce the amount of cement, so as to reduce the energy consumption of fuel and electricity in the firing stage of cement clinker, and it is estimated that each ton of cemented material can reduce carbon emissions by about 57%, which has become the most direct and effective way to reduce the carbon contained in buildings. In addition, the unique low-carbon construction method, which integrates the differentiated technology of RTC Intelligent Property and “Know-How”, has made significant contributions to reducing carbon content in buildings, creating resilient buildings, shortening construction periods, reducing environmental impacts, and reducing manpower to cope with the declining birthrate trend.

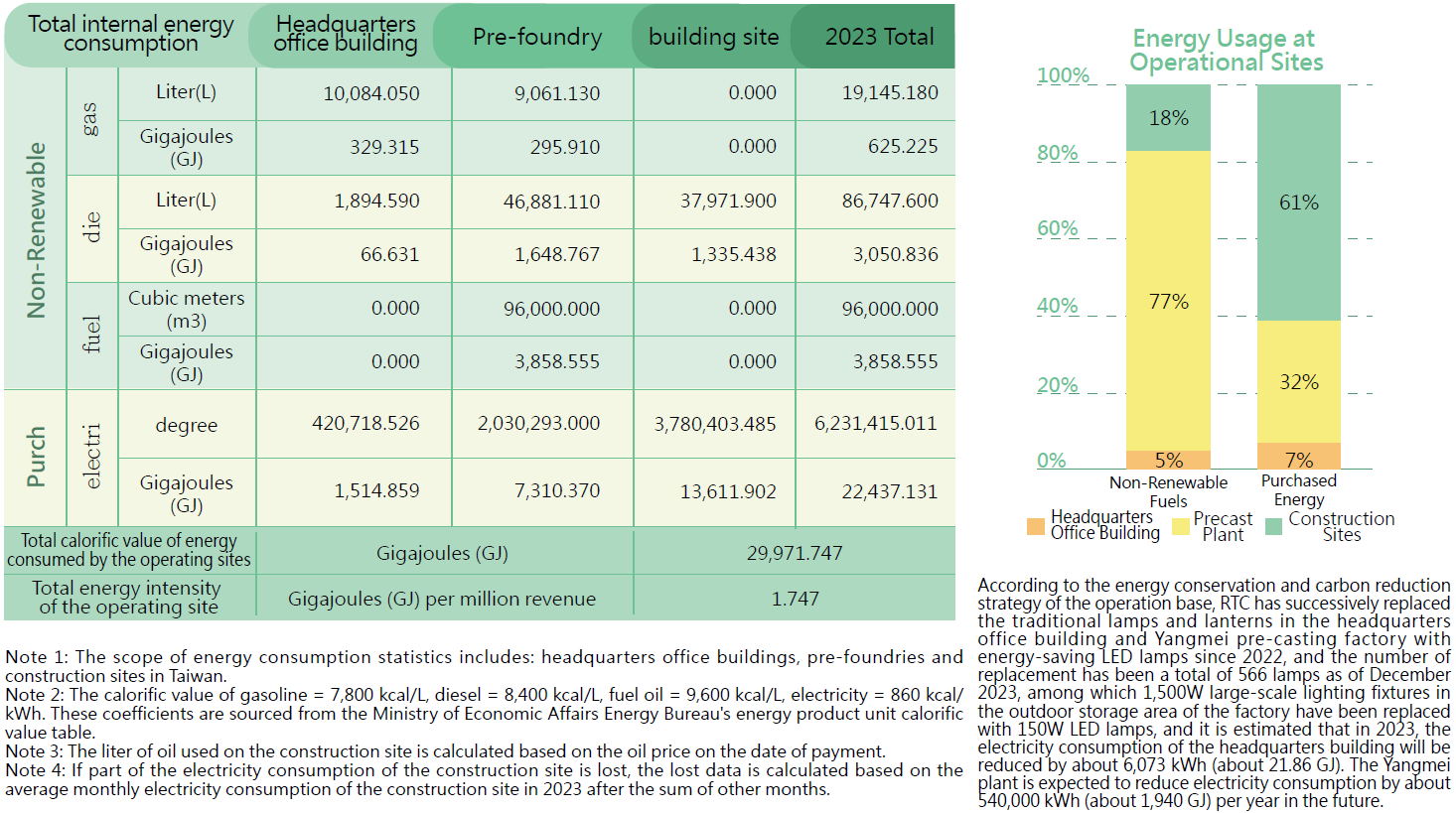

Energy use and the effectiveness of energy conservation measures

In 2023, the total energy consumption of RTC will be 28,533.954 GJ, which is mainly consumed by purchased electricity, accounting for about 73.59% of the total energy consumption, followed by fuel oil for the provision of machinery, accounting for about 13.52%, in the future, RTC will continue to track the use and trend of various energy sources, and reflect on energy-saving solutions.

Greenhouse gas management

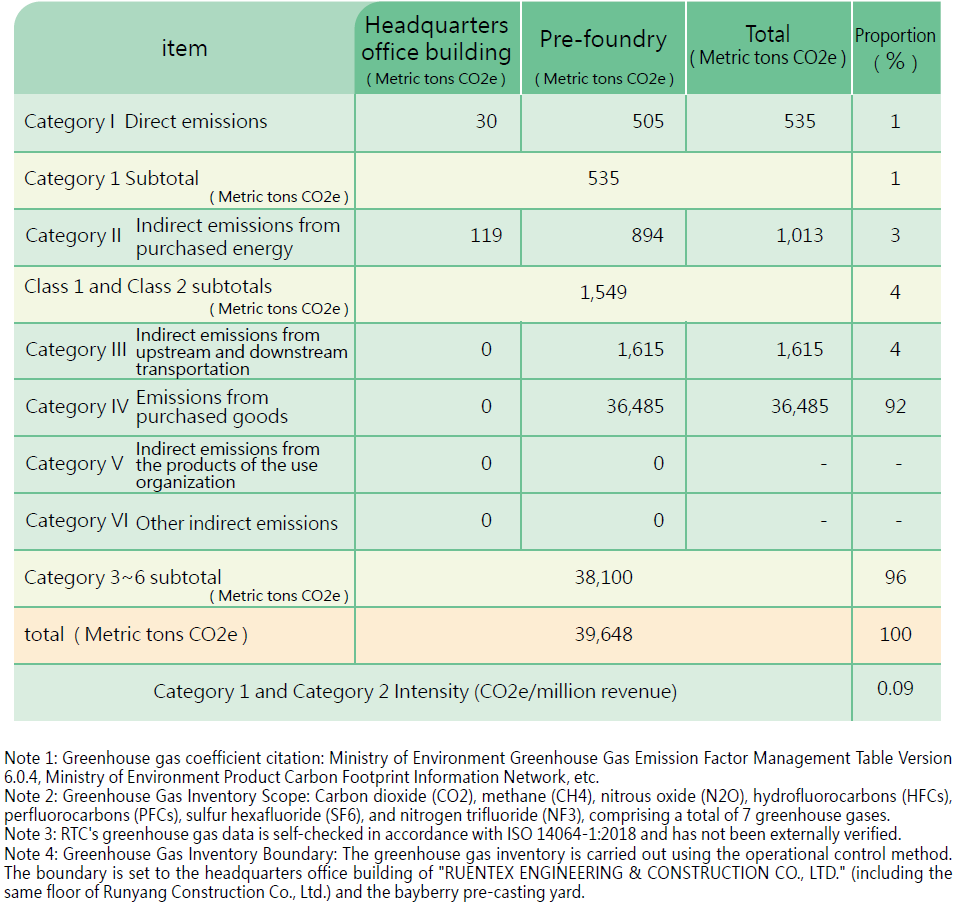

In 2024, RTC will complete the greenhouse gas inventory operation in 2023 in accordance with ISO14064 1:2018 for the first time, and will check the greenhouse gas emissions of RTC year by year in the future, and set medium and long-term carbon reduction targets. RTC’s total greenhouse gas emissions in 2023 will be 39,649 metric tons of CO2e, with Category 1 direct emissions accounting for 1% of the total, mainly from stationary fuel combustion sources; Category 2 Indirect energy emissions account for 3% of the total, mainly from electricity consumption at the operating sites; RTC’s carbon emission intensity is 009 (CO2e/million revenues); Category 3~6 emissions account for 96% of the total, and are derived from goods procured by Category 4 organizations, including steel bar, cement, furnace stone powder, sand and concrete. In the future, based on the results of the 2023 carbon emission inventory, we will formulate carbon reduction methods and targets, and track the achievement of short-, medium- and longterm carbon reduction goals through routine carbon inventory, so as to make a contribution to global carbon reduction.

Product carbon footprint

With the goal of green pre-casting production, RTC has transformed the pre-casting factory into greening, andhas invested in product carbon footprint verification since 2023, responding to the global attention to product carbon footprint in recent years. In accordance with the principles of ISO 14067, RTC reviews the methodological framework, sets a reasonable calculation methodology for the raw materials, manufacturing, use, distribution and sales, disposal and other stages of the life cycle of precasting construction, and expects to complete the first product verification in mid-2024, while collecting and establishing benchmark carbon data, clarifying the emissions of products in the life cycle stage, so as to reduce greenhouse gases from the pain points.

Effectiveness of greenhouse gas reduction measures

After replacing the lamps, if the national electricity emission coefficient in 2023 is 0.494 kg- CO2e/kWh, it is estimated that the office building of RTC headquarters will be reduced by 3,000 kg-CO2e in 2023. The bayberry precast plant will reduce CO2e by 266,278 kg-CO2e per year in the future. In addition, after the completion of the solar panel installation, the Yangmei plant will provide about 1.6 million kWh of electricity for self-consumption, which can reduce about 790,400 kg-CO2e per year, and can effectively track the carbon footprint reduction changes of a single product in the future when calculating the carbon footprint of precast products according to the ISO 14067 methodology. With 2023 as the base year, RTC plans to reduce greenhouse gas emissions by 89% by 2026 through energy conservation and the introduction of renewable energy. In terms of materials, the bayberry pre-casting plant will be transformed into a green factory by reducing greenhouse gas emissions by 27% by 2026 through loss reduction and research and development of low-carbon concrete.

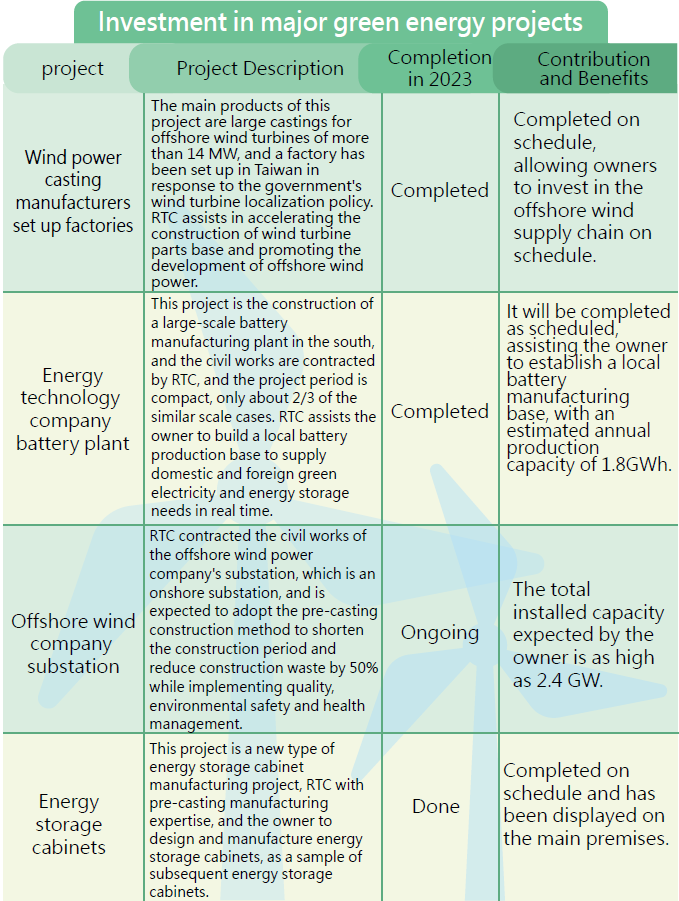

In addition to planning the construction of the company’s internal solar version, RTC chose to invest resources in renewable energy-related projects under the limited construction resources. With its own technology, RTC helps renewable energy related owners quickly complete the construction of the plant and accelerate the promotion of renewable energy production in Taiwan. In 2023, the backlog of renewable energyrelated projects is NT$939 million.